In today's fast-paced industrial landscape, ensuring the integrity and reliability of materials is critical. From aerospace and automotive industries to oil and gas, the safety of infrastructure and equipment is non-negotiable. One of the most trusted non-destructive...

Homepage > Connecting Rods

The connecting shaft needs to be magnetized in two directions perpendicular to each other. A circular magnetic field is used to detect longitudinal flaws in the part.

Circular magnetic field is generated by passing a current through the length of the connecting rod.

Calculation of head shot current is done as per the formula given in ASTM standards.

Head Shot Current = 20 X Diameter(mm)

In the above formula, the diameter should be taken as the maximum diameter of the connecting rod.

Longitudinal magnetic field, required for detection of transverse defects is generated by using an encircling coil.

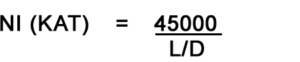

Formula for calculation of coil current

In the above formula, the diameter should be taken as the average diameter of the connecting rod.

![]()

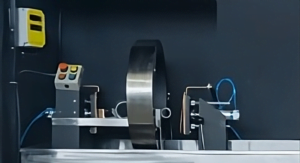

A horizontal bench type machine is used to perform magnetic particle testing on connecting rods. Connecting rod is placed on the steady rollers fitted on the head & tailstock of the machine. A pneumatically operated arrangement is used to clamp the connecting rod from both ends. Pneumatic clamping ensures that there is no sparking when high current is passed through the connecting rod. Use of braided copper pads is also recommended to eliminate arcing sparks.

Conventional Technique

A two vector PLC based bench type magnetic crack detector machine is used to perform testing on the connecting rods.

Testing Procedure for conventional machines

- Clean up & dry the connecting rod’s surface before inspecting.

- The connecting rodis placed on the fixture.

- Now apply magnetic solution bath to the connecting rod.

- Press the ‘Cycle Start’ button.

- The connecting rod automatically gets clamped.

- Stop the flow of bath.

- Now, the current passes through the connecting rod.

- It shows up on the digital metering unit.

- The connecting rod automatically gets de-clamped.

- Inspect the connecting rod under UV light for longitudinal defects. Rotate on steady rollers.

- Now, again apply bath to the job.

- Press the ‘Cycle Start’ button.

- Stop the flow of bath.

- Now the current passes through the coil.

- It shows up on the digital metering unit.

- Inspect the connecting rod under UV light for transverse defects. Rotate on Rollers

Multidirectional Technique

Testing Procedure for Multidirectional machines

- Clean up & dry the connecting rod’s surface before inspection

- Place the connecting rod on the steady rollers.

- Now apply a bath to the connecting rod.

- Press the ‘Cycle Start’ button.

- The connecting rod will automatically get clamped.

- Stop the flow of the bath.

- Now the current will pass through the connecting rod& the coil in multidirectional mode.

- It will show up on the digital metering unit.

- The connecting rod will automatically get de-clamped.

- Inspect the connecting rod under UV light for defects in all directions. Rotate on rollers.

- Demagnetize

suitable products

Standard MPI Machines

Engineered for precision and efficiency, the Standard Bench Type Magnetic Particle Testing Machine is suitable for entry level testing.

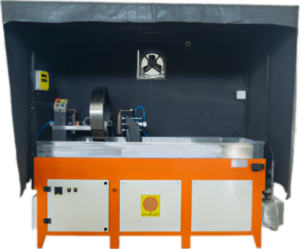

PLC Controlled MPI Bench

With PLC Controlled bench type Magnetic Particle Inspection Machine, you can accurately control the process parameters for reilable results.

Multidirectional MPI Bench

The ultimate solution for robust non-destructive testing, this machine offers multi-directional magnetization for inspection in all directions in one shot..

Demagnetizers

Demagnetizers stand as a key tool in maintaining excellence in production, with the flexibility to handle different materials and magnetism levels, coupled with energy-efficient and user-friendly design.

DIVE DEEPER: GET YOUR HANDS ON OUR PRODUCT BROCHURE!

Explore More, Discover Better!

- In-Depth Details

- Product Insights

- Expert Recommendations

Download Our Brochure Now!

Blogs

The Essential Role of Magkraft’s MPI Products in Non-Destructive Testing

In the realm of Non-Destructive Testing (NDT), Magnetic Particle Inspection (MPI) stands out as a highly effective method for detecting surface and near-surface defects in ferromagnetic materials. MPI products are crucial components in this process, enabling...

Addressing Common Challenges in NDT: Solutions by Magkraft

Non-destructive testing (NDT) is critical in ensuring the integrity and reliability of materials and components across various industries. However, like any technical field, NDT has challenges that can impact inspection outcomes and efficiency. In this article, we'll...