Homepage > MPI Machine for aerospace parts

MPI Machine for aerospace parts

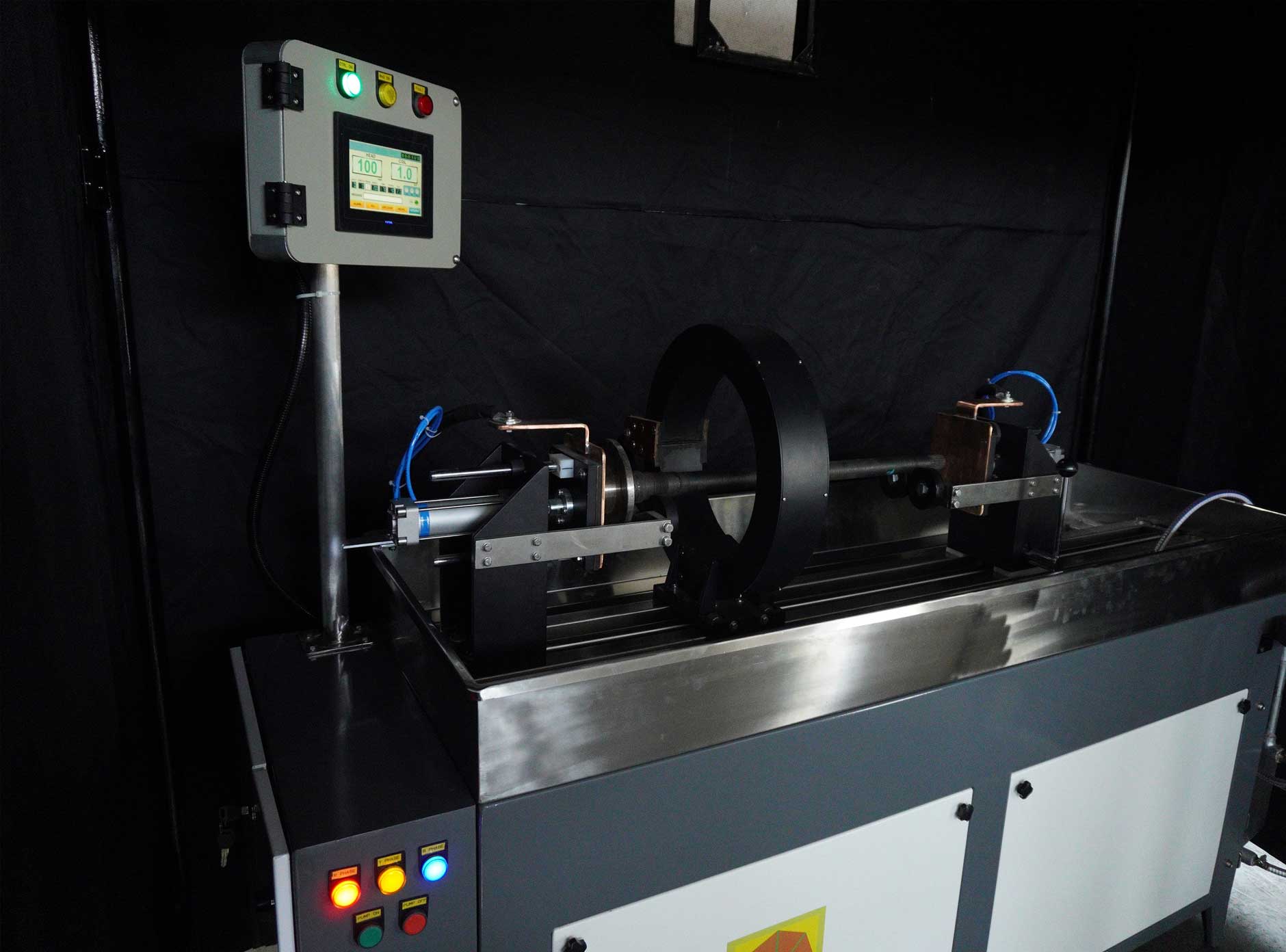

These machines are suitable for the detection of surface & subsurface defects in aerospace parts. These machines comply with ASTM E1444 & E709.

They generate AC & FWDC current.

These benches are two vector machines. A circular magnetic field is generated by clamping the part between the headstock & tailstock & passing a current through the part. Parts with a central bore can be tested using the threaded bar method. The longitudinal magnetic field is generated by using an encircling coil. AC to FWDC changeover is accomplished by solid-state circuitry.

Adjustable magnetization time of up to 2.0 seconds allows for the complete

development of indications.

Available in various amperages, part lengths & coil diameters.

Dark room with a ventilation fan & white light is included in all models for

testing with fluorescent powders.

Features

- PLC-Based Control. Automatic Cycle for faster testing.

- 7 Inch Touch Screen for control & display.

- Operator controlled an automatic double shot

- 50 Program memory to store settings for different parts.

- Error displayed on the touch screen for easy diagnostics.

- Independent current control for Circular and longitudinal magnetization.

- Digital, stepless current control.

- Both sides have Pneumatic clamping.

- Stainless Steel liquid storage tank.

- Stainless Steel collection tray

- Reverse agitation bath system.

- Continuously movable tailstock with cam lock

- Steady Rollers for job placement

- Integrated decaying-AC demagnetization with automatic changeover to AC

- AC to FWDC changeover uses solid-state circuitry.

- Feedback loop-based current control with current failure indicator.

- Standard make PLC & HMI. Easily serviceable.

- Range Selection switch for enhanced pulse width in low amperage settings.

- AC Drive for Pump Control

Specifications

| Headshot Current Capacity | Models starting from 3000A going up to 6000A |

| Maximum Part Length Accommodation | Starting from 600mm going up to 1500mm |

| Maximum Part Diameter | Starting from 150mm going up to 300mm |

| Maximum Part Weight | 450Kg |

| Storage Bath Capacity | 25 L |

| Shot Time | Adjustable from 0.5 sec 2.0 sec |

| Power Supply | 2 Phase 2 Wire 415V AC/220V AC |

| Frequency | 50Hz or 60Hz |

| Pneumatic Pressure Required | 4-6 Kg/cm2 |

| Coil Diameters | 300mm, 400mm, 500mm |

| Control Voltage | 24V DC |

| Touch Screen Display Size | 7” Diagonal |

Optional Features:

- Separate Digital Ammeters

- Mag-shot-activating front push bar with 1-touch control to enable/disable this feature.

- Reversing DC Demagnetization.

- Database System with advanced touch screen operating interface and barcode scanner eliminates time spent on manual inputs.

- User-controlled security systems with password protection, supervisor locks, and customizable operator access profiles

- Daily reminder alarms verify UV light, visible light, and particle bath concentration for process control requirements.

- Error displayed on the touch screen for easy diagnostics.

BENEFITS & APPLICATIONS

Benefits

- SCR-based digital current control for accuracy & precision

- Feedback loop ensures repeatability

- Reverse agitation system keeps the powder always dissolved in the carrier fluid.

- Pneumatic clamping ensures no sparks

- 7-inch Touch Screen for operator comfort.

- Complies with aerospace standards for magnetic particle testing

- Low voltage output for operator safety

- Operator controlled the Poka yoke for the demagnetization cycle.

Applications

- Aerospace parts

- Oil field equipment parts

- Marine Industry parts

Product models

Horizontal Clamping Models

Model | Head Shot Capacity | Coil Shot Capacity | Coil Inside Diameter | Maximum Part Length | Maximum Part Diameter |

MK-30-C-60-AF | 3000A AC & FWDC | 10.0 KAT AC & FWDC | 300mm | 600mm | 150mm |

MK-30-C-120-AF | 3000A AC & FWDC | 10.0 KAT AC & FWDC | 300mm | 1200mm | 150mm |

MK-40-C-100-AF | 4000A AC & FWDC | 10.0 KAT AC & FWDC | 400mm | 1000mm | 200mm |

MK-40-C-150-AF | 4000A AC & FWDC | 10.0 KAT AC & FWDC | 400mm | 1500mm | 200mm |

MK-50-C-100-AF | 5000A AC & FWDC | 10.0 KAT AC & FWDC | 400mm | 1000mm | 250mm |

MK-50-C-150-AF | 5000A AC & FWDC | 10.0 KAT AC & FWDC | 400mm | 1500mm | 250mm |

MK-60-C-100-AF | 6000A AC & FWDC | 10.0 KAT AC & FWDC | 500mm | 1000mm | 300mm |

MK-60-C-150-AF | 6000A AC & FWDC | 10.0 KAT AC & FWDC | 500mm | 1500mm | 300mm |

related products

Standard MPI Machines

Engineered for precision and efficiency, the Standard Bench Type Magnetic Particle Testing Machine is suitable for entry level testing.

PLC Controlled MPI Bench

With PLC Controlled bench type Magnetic Particle Inspection Machine, you can accurately control the process parameters for reilable results.

Demagnetizers

Demagnetizers are used to demagnetize the parts after performing magnetic particle testing. Our wide range caters to the smallest as well as largest comopnents.

UV Lights

Our range of UV LED Lights is engineered to provide illumination for testing with fluorescent dies & powders in the field of non-destructive testing.

DIVE DEEPER: GET YOUR HANDS ON OUR PRODUCT BROCHURE!

Explore More, Discover Better!

- In-Depth Details

- Product Insights

- Expert Recommendations

Download our corporate brochure

RESOURCES

Addressing Common Challenges in NDT: Solutions by Magkraft

Non-destructive testing (NDT) is critical in ensuring the integrity and reliability of materials and components across various industries. However, like any technical field, NDT has challenges that can impact inspection outcomes and efficiency. In this article, we'll...

Exploring the Applications of Eddy Current Testing: A Focus on Magkraft’s Offerings

Eddy Current Testing (ECT) is a widely used non-destructive testing (NDT) technique to inspect conductive materials for surface and subsurface defects. With its versatility and effectiveness, ECT finds applications across various industries, including aerospace,...

Cost-Effectiveness and Safety: The Dual Benefits of Using Magnetic Crack Detectors in Your Operations

Cost-Effectiveness and Safety: The Dual Benefits of Using Magnetic Crack Detectors in Your Operations In the modern industrial landscape, where safety and cost management are paramount, non-destructive testing (NDT) tools like magnetic crack detector become critical....