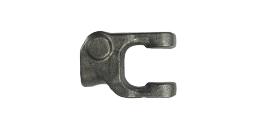

The half yoke needs to be magnetized in two directions perpendicular to each other. A circular magnetic field is used to detect longitudinal flaws in the part.

The half yoke needs to be magnetized in two directions perpendicular to each other. A circular magnetic field is used to detect longitudinal flaws in the part.

Circular magnetic field is generated by passing a current through the length of the half yoke.

Calculation of head shot current is done as per the formula given in ASTM standards.

Head Shot Current = 20 X Diameter(mm)

In the above formula, the diameter should be taken as diameter of the boss portion.

Longitudinal magnetic field, required for detection of transverse defects is generated by using an encircling coil.

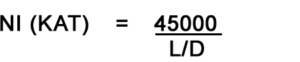

Formula for calculation of coil current

In the above formula, the diameter should be taken as the average diameter of the half yoke. Average diameter can be calculated by the following formula.

![]()

The geometry of the yoke is extremely unique. It is a single unit at one end and splits into two on the other end. If one of the arms of half yokes is not in contact with the tailstock, the entire current will pass through one arm, leaving the other arm unmagnetized. The amount of current passed through each arm is determined by its resistance and also the resistance of the contact. There is no method to ensure that an equal amount of current passes through each arm. This can result in skipping of detection of flaws on one arm.

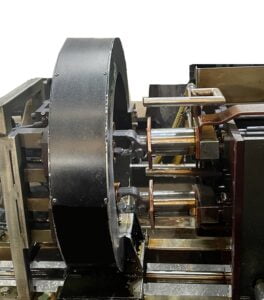

A tailor made horizontal bench type machine is used to perform magnetic particle testing on half yokes. In this machine, the tailstock is split in two parts, each having its own pneumatic cylinder. This ensures that both the arms are clamped properly. Current passing through each arm is measured & controlled separately to ensure that the current split is even. A Poke yoke systems indicates if there is any anomaly in the distribution of current in the two arms.

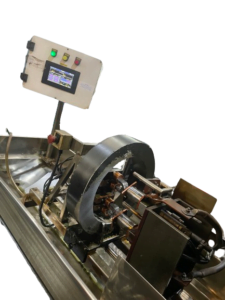

Multi-directional magnetization is a special technique employed to identify defects in all orientations within a single examination. This stands in contrast to the combined magnetization shot utilized in traditional machines, which doesn’t align with ASTM standards. This technique proves effective in identifying both longitudinal and transverse cracks within one examination.

In this machine, multidirectional magnetization is used so that defects in all directions can be detected in one shot.

Testing Procedure for Multidirectional machines

- Clean up & dry the half yoke’s surface before inspecting.

- The half yokeis placed on the fixture.

- Now apply magnetic solution bath to the half yoke.

- Press the ‘Cycle Start’ button.

- The half yoke automatically gets clamped.

- The coil also moves to its position.

- Stop the flow of bath.

- Now, the current passes through the half yoke & the coil in multidirectional mode.

- It shows up on the digital metering unit.

- The half yoke automatically gets de-clamped.

- Take out the half yoke&inspect it under UV light for all defects.

- Demagnetize

suitable products

Standard MPI Machines

Engineered for precision and efficiency, the Standard Bench Type Magnetic Particle Testing Machine is suitable for entry level testing.

PLC Controlled MPI Bench

With PLC Controlled bench type Magnetic Particle Inspection Machine, you can accurately control the process parameters for reilable results.

Multidirectional MPI Bench

The ultimate solution for robust non-destructive testing, this machine offers multi-directional magnetization for inspection in all directions in one shot..

Demagnetizers

Demagnetizers stand as a key tool in maintaining excellence in production, with the flexibility to handle different materials and magnetism levels, coupled with energy-efficient and user-friendly design.

DIVE DEEPER: GET YOUR HANDS ON OUR PRODUCT BROCHURE!

Explore More, Discover Better!

- In-Depth Details

- Product Insights

- Expert Recommendations

Download Our Brochure Now!

RESOURCES

Addressing Common Challenges in NDT: Solutions by Magkraft

Non-destructive testing (NDT) is critical in ensuring the integrity and reliability of materials and components across various industries. However, like any technical field, NDT has challenges that can impact inspection outcomes and efficiency. In this article, we'll...

Exploring the Applications of Eddy Current Testing: A Focus on Magkraft’s Offerings

Eddy Current Testing (ECT) is a widely used non-destructive testing (NDT) technique to inspect conductive materials for surface and subsurface defects. With its versatility and effectiveness, ECT finds applications across various industries, including aerospace,...

Cost-Effectiveness and Safety: The Dual Benefits of Using Magnetic Crack Detectors in Your Operations

Cost-Effectiveness and Safety: The Dual Benefits of Using Magnetic Crack Detectors in Your Operations In the modern industrial landscape, where safety and cost management are paramount, non-destructive testing (NDT) tools like magnetic crack detector become critical....