Magnetic Field Evaluation Tools

Ensuring adequate strength and correct orientation of a magnetic field is crucial during magnetic particle testing.

Accurately measuring field intensity at a specific point within a material is challenging. To measure field strength, it’s necessary to intercept flux lines, which typically involves material damage. However, cutting a small slot or hole and measuring the resulting leakage field with a Gauss meter offers a practical estimate of field strength. Multiple tools and methods are available for assessing the field surrounding a component.

Gauss Meter

Commonly used to gauge tangential field strength on the surface, a Gauss meter with a Hall Effect probe exploits the transverse electric field created in a conductor placed within a magnetic field. Also known as Tesla meters, these devices measure the strength of a field tangential to the magnetized object’s surface. This approach quantifies the field’s intensity in the adjacent air. While providing benefits such as quantitative measurement of tangential magnetizing force and the ability to measure residual fields, Gauss meters must be calibrated periodically and aren’t suitable for establishing field balance in multidirectional setups.

Quantitative Quality Indicator (QQI)

Preferred for ensuring proper field direction and strength, the QQI or Artificial Flaw Standard is a reliable method. It’s also essential for balancing field intensity and direction in multi-directional magnetization equipment. Used in conjunction with a Gauss meter, QQIs establish inspection procedures for specific components, exclusively with the wet method and continuous magnetization. QQIs are etched AISI 1005 steel strips, designed with patterns like concentric circles. Intimate contact with the part is crucial; when adequately magnetized, particles adhere to the engraved pattern, indicating field direction.

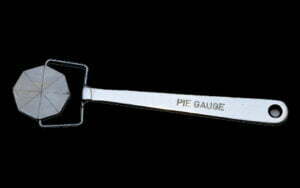

Pie Gauge

A pie gage consists of a highly permeable disk divided into sections by nonferromagnetic material. These divisions serve as artificial defects radiating from the center. With a diameter of 3/4 to 1 inch, it’s placed on a test piece, magnetized, and particles applied to show the field’s orientation. Ideal for flat surfaces and dry powder applications, the pie gage is less suitable for complex shapes, wet-method use, or assessing field magnitude. While simple and durable, it retains residual magnetism and is unsuitable for multidirectional balance determination.

The choice of evaluation tool depends on specific needs, with each method offering unique advantages and limitations.