In today's fast-paced industrial landscape, ensuring the integrity and reliability of materials is critical. From aerospace and automotive industries to oil and gas, the safety of infrastructure and equipment is non-negotiable. One of the most trusted non-destructive...

Homepage >MPI Machines

MPI Machines

At Compac Technologies India Ltd, we strive to stay at the forefront of non-destructive testing (NDT) technology, and our multidirectional MPI machines are a testament to our commitment to innovation. As manufacturers and sellers of cutting-edge MPI equipment, we have developed multidirectional MPI machines that offer unparalleled inspection capabilities for complex components and surfaces defects.

Features of MPI Machines

- High Sensitivity Detection: Unmatched ability to detect even the smallest cracks and flaws.

- User-Friendly Interface: Simplified operation with intuitive controls and clear displays.

- Versatile Configuration Options: Customizable features such as adjustable current output and multi-directional magnetization.

- Built-in Safety Measures: Includes emergency stop buttons, overload protection, and safety interlocks.

- Robust Construction: Designed for long-term durability and reliability.

Product Specifications

| Specification | Description |

| Detection Method | Magnetic Particle Inspection (MPI) |

| Current Output Range | 0 – 5000 Amps (customizable) |

| Magnetization Modes | Multi-directional, longitudinal, and circular |

| Compliance Standards | ASTM E709, ASTM E1444, etc. |

| Power Requirements | 220-240V, single or three-phase |

| Weight and Dimensions | Vary by model and customization |

BENEFITS & Applications of MPI MAchines

Benefits of using MPI Machines

- Enhanced Quality Assurance: Guarantees compliance with industry standards.

- Reduced Inspection Time: Speeds up the inspection process without compromising accuracy.

- Adaptability: Suitable for a wide range of materials and part geometries.

- Cost-Efficiency: Minimizes rework and reduces waste through accurate detection.

- Safety: Prioritizes operator safety with built-in protections.

Applications of MPI Machines

- Automotive Industry: Inspection of engine components, gears, and axles.

- Aerospace Sector: Examination of aircraft parts for structural integrity.

- Manufacturing and Fabrication: Quality control in various production processes.

- Oil and Gas Industry: Inspection of pipelines, welds, and drilling equipment.

- Railways: Assessment of rail tracks, wheels, and other essential components.

Product Models

Magrkraft Product

Description

Part Number

AHD-5020

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

F04106

AHD-5020

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

F04106

AHD-5020

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

F04106

AHD-5020

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

F04106

AHD-5020

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

F04106

AHD-5020

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

F04106

information

Magrkraft Product

AHD-5020

Description

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

Part Number

F04106

F04106

Magrkraft Product

AHD-5020

Description

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

Part Number

F04106

Magrkraft Product

AHD-5020

Description

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

Part Number

F04106

Magrkraft Product

AHD-5020

Description

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

Part Number

F04106

Magrkraft Product

AHD-5020

Description

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

Part Number:

F04106

Magrkraft Product

AHD-5020

Description

Combination shot Magnetization of 2000 Amps 1 Phase AC & HWDC, 2 Outputs – Contacts, 10” (26 cm) ID Coil, Voltages Available (415V or 380V), Maximum Part Length: 500mm, Maximum Part Diameter : 75mm

Part Number

F04106

Our Other ProductS

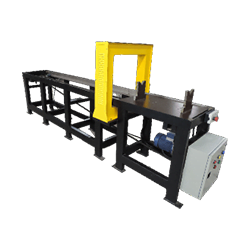

Standard MPI Machines

Engineered for precision and efficiency, the Standard Bench Type Machine is a core solution for non-destructive testing in various industries.

Multi Directional Bench Type Machine

The ultimate solution for robust non-destructive testing, this machine offers multi-directional magnetization for a comprehensive inspection.

Demagnetizers

Demagnetizers stand as a key tool in maintaining excellence in production, with the flexibility to handle different materials and magnetism levels, coupled with energy-efficient and user-friendly design.

UV Lights

Our UV Lights range is engineered to provide highly specialized illumination for various industrial, medical, and research applications.

DIVE DEEPER: GET YOUR HANDS ON OUR PRODUCT BROCHURE!

Explore More, Discover Better!

- In-Depth Details

- Product Insights

- Expert Recommendations

Download our Brochure Now!

RECENT ARTICLES

The Essential Role of Magkraft’s MPI Products in Non-Destructive Testing

In the realm of Non-Destructive Testing (NDT), Magnetic Particle Inspection (MPI) stands out as a highly effective method for detecting surface and near-surface defects in ferromagnetic materials. MPI products are crucial components in this process, enabling...

Addressing Common Challenges in NDT: Solutions by Magkraft

Non-destructive testing (NDT) is critical in ensuring the integrity and reliability of materials and components across various industries. However, like any technical field, NDT has challenges that can impact inspection outcomes and efficiency. In this article, we'll...